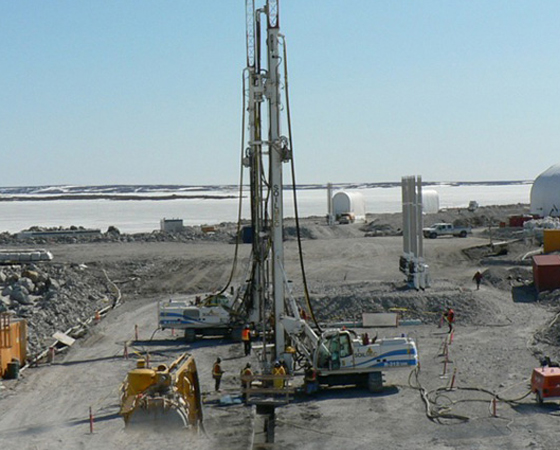

Jet Grouting

Jet Grouting uses high velocity fluid jets to construct cemented soil of varying geometries in the ground. Common uses

• Control of groundwat

Services Details

Jet Grouting uses high velocity fluid jets to construct cemented soil of varying geometries in the ground.

Common uses

• Control of groundwater or excavation of unstable soil (water-bearing or otherwise)

• Underpin foundations

• Provide excavation support

• Seal the bottom of planned excavations

Process

Jet grouting creates in situ geometries of soil Crete (grouted soil), using a grouting monitor attached to the end of a drill stem. The jet grout monitor is advanced to the maximum treatment depth. Then high velocity jets (cement grout with optional water and air) are initiated from ports in the monitor. The jets erode and mix the in situ soil with grout as the drill stem and monitor are rotated and raised.

Depending on the application and types of soils, one of three variations is used: the single fluid system (slurry grout jet), the double fluid system (slurry grout jet surrounded by an air jet) and the triple fluid system (water jet surrounded by an air jet, with a separate grout port). The jet grouting process constructs soilcrete panels, full columns, or partial columns with designed strength and/or permeability.

The soilcrete geometry and physical properties are designed based on the in-situ soils. Because it is an erosion-based system, soil erodibility plays a major role in predicting geometry, quality, and production. Cohesion less soil is typically more erodible by jet grouting than cohesive soils.

Advantages

• Effective across the widest range of soil types of any grouting system, including silts and most clays

• Ability to construct soil Crete in limited spaces and around subsurface obstacles such as utilities

• Low headroom equipment enables construction in limited spaces such as basements

• Can target specific soil layers at depth without having to treat soils above

• Jet grouting can be combined with other techniques to provide a comprehensive and cost-effective geotechnical solution

• Can usually be done without disrupting normal facility operations

• Containerized, highly mobile support equipment reduces mobilization and demobilization costs and time